Industrial

Experiences

February 1996 -

June 2021

During teaching at sharif University of

Technology the following Industrial projects

have also been completed. |

|

|

Investigation on Drilling rig Maintenance

Methods & Certificates

This is a

maintenance project with one of the Iranian Oil

Drilling Company in order to optimize their

current maintenance costs. At the end of the

project we are expected to give a

new

methodology and strategy for their maintenance.

Figure 1 shows one of these drilling rigs.

Fig 1- Drilling rig

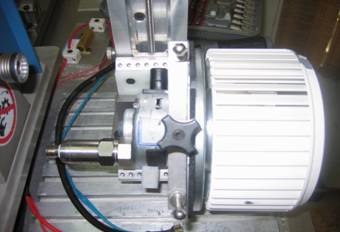

Dc

Motor Vibration Analysis for Ettehad Motor

The very small

electro motor can be seen in Fig. (2) used in

vehicles for ventilation. The manufacturer used

to have noise and vibration problem on them. We

carried out vibration measurement and analysis.

Our analysis based recommendation has been

implemented by the manufacturer. Now they are

producing the unit without any noise and

vibration

problem (Figure 2).

Fig. 2- Ettehad Motor electromotor

Effect of earthquake on residential buildings

A residential

building has been erected in the earthquake

laboratory of sharif university of Technology

for earth quake experimental simulation as shown

if Fig. (3) and we were

interested in the gas

piping behavior in this building. Through the

test we have investigated the piping behavior

from the start of the earth quake simulation

till the end of test (Figure 3).

Fig. 3- Residential building

Touchal Tele cabin Condition Monitoring

We are involved in

vibration based monitoring in Touchal Tele

cabin company for two years. This includes

vibration measurement analysis and

recommendation to the owner for

optimized

maintenance activities and maximum efficiency.

Figure ( 4) shows one of their cabins in

operation.

Fig. 4- Touchal Tele cabin

Vibration Condition Monitoring for Abadan Power

Plant

We have run

condition monitoring for more than two years in

Abadan power plant as shown in Fig. (5). The

procedure was to measure the vibration in

important machines

regularly and predict any

necessary maintenance work in the plant. This

reduced the forced outage from 2.5% to .5% in

this plant

Fig. 5- Abadan Power plant

Material

tests in solid mechanics laboratory

During 5 years work and superviso in the solid

mechanics laboratory variety of material tests

including tensile, compression, torsion,

pressure and fatigue tests were conducted for

different industries. Fig. 1 shows checking the

u bent test of a welded speciman.

Fig. 1 visual check for crack in a u bent test

Fig. 2 Performing a tensile test with a 2000KN Machine

Blade Failure

investigation in Turbine 101-j Razi

petrochemical company

Blade failure in low pressure part of a steam

turbine has been investigated in this study. For

this investigation all related information and

data have been collected from the plant.

These

information include process parameters,

vibration data, and maintenance history.

Microstructure study, chemical composition

determination and cracked section study have

also

been carried out. The results show creep

cavities in the failed Blades. The damaged blade

is shown in Figure3

Fig. 3 Damaged blades of gas turbine in Razi Petrochemical

company.

Vibration

Investigation in Alstom Locomotive in Tehran

The aim of this

project was to give the vibration measured

values and analysis at different locations of a

locomotive in order to find the reasons of

radiator leakage. For comparison

some

measurements are carried out in two locomotives.

The measured values include velocity and

acceleration in unloaded (idle) and loaded

(notch 8) conditions in three

directions.

According to measured values of vibration and

considering standard ISO 10816-6, the engine of

faulty locomotive is not running smoothly. This

conclusion can also be achieved by comparing the

vibration of the engines in the faulty

locomotive and healthy locomotive at similar

locations and operating conditions. Gear mesh

frequency can be seen in the

frequency spectrum

of the faulty unit. According to the

measurements and analysis it can be concluded

that the faulty gear needs to be replaced.

Figure 4 shows Dr Behzad attending

at Tehran

railway maintenance center and figure 5 shos two

of the project team members.

Fig. 4

Dr behzad attending at Tehran Rail way

Maintenance department.

Fig. 5 Dr Behzad (left) with Salmasi and khamseh in the

train cabin.

Modal analysis

and Finite element analysis of gas turbine

blades

In this project Natural frequencis and

mode shapes for a gas turbine blade has been

obtained by experimental and analytical method.

Figure 6 shows the test set up for the

experimental method in the vibration laboratory

at sharif university of technology.

Fig. 6 test set

up for finding the natural frequencies fo a gas

turbine blade.

The aim of

this project was to investigate the vibration of

hudro power plants. The main sources of

vibration in these plants are found and

measurement are carried out to investigate

the

high vibration of the turbine generator set.

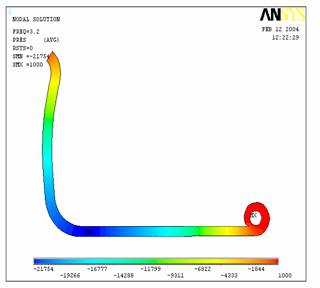

Figure 7 shows the runner of of the abbaspour

250MW hydro power plant and Figure 8 gives the

result of numerical model of the

water carriage

pipe.

Fig. 7 Runner

of Abbaspour hydro power plant.

Fig. 8 numerical results for the simmulation of

Abbaspour hydro power plant water carriage

pipes

Vibration

investigation in utility pump of khorasan

petrochemical complex.

In

this industrial project, abnormal vibrations of

two similar centrifugal pumps in a petrochemical

factory have been studied. The piping

arrangement around the pump is shown

in figure

9.These two pumps discharge sump from the

neutralizing tanks and work as standby.

Excessive vibration of the pumps brought some

concerns and limited the operation.

Some primary

mechanical repairs and adjustments had been done

on the pumps but the problem was remained

unsolved. The purpose of the study was to find

source of vibration

and recommend a practical

remedy to solve the problem. To this mean,

vibrations on electromotor bearing, pump

bearings, pipeline and foundation in various

operational conditions

were measured. Historical

records of pump vibrations and repairing actions

were also considered. The analysis showed that

the pump was source of vibration. The

predominant

frequency component of vibration was

associated to blade passage frequency. This

frequency is caused by fluidic problems in the

pump.

Measurements also showed

that operating point of the pump, which is

controlled by a throttling valve at the

discharge, has major effect on the pump

vibration severity. When the

pump operates at

off-design conditions vibration amplitude rises

dangerously. Near BEP vibration amplitude

reaches to its minimum, which is greater than

recommended values yet.

After investigation, the

source of problem was found to be fluidic

problems, operating point of the pump and

throttling valve. Using of a variable-speed

drive for electromotor was

proposed to reduce

the pump speed from 3000 RPM to 1500 RPM to

solve the problem.

Fig. 9 Piping

arrangement around the pump of Khorasan

petrochemical plant.

Mechanical Fault

simulator rig [design,manufacture,test].

The main objective

of this project was to design manufacture and

tes a rig for fault simmulation of rotating

machinery. The design manufacture and test of

this apparatus were done

at Sharif university of

technology. This apparatus has been made for NRI(

a research center for power stations. Figure 10

shows the rig while being tested by Dr Behzad.

Fig. 10 fault

simmulator rig.

|