Seismic Analysis and Design of Steel Structures

Introduction and development of shear slotted bolted connection

Slotted Bolted Connections (SBCs) have been developed and used as an axial friction damper in braced frames since 80s. To employ the benefits of SBCs in Moment Resisting Frames (MRFs), Rotational Slotted Bolted Connections (RSBCs) have been developed more recently with limited application in members that flexural behavior is dominated to shear. In this paper Shear Slotted Bolted Connection (SSBC) is introduced as a new type of friction dampers to employ the benefits of SBCs in lateral load resisting systems with predominant shear behavior members that dissipate energy by traditional yielding mechanisms. The SSBC is a modified bolted connection that dissipates energy through friction in which friction is activated by shear force. The applications of the proposed system as a shear link in link beams of Eccentrically Braced Frames (EBFs), in the beams of MRFs, and coupling beams of coupled concrete shear walls are introduced. To show the efficiency of SSBC, an existing EBF with tubular link beam is equipped with SSBC and its behavior is studied via models created in general purpose finite element program ABAQUS. Also three MRFs with different beam lengths are modified using SSBC and their monotonic and cyclic behavior are investigated using finite element method. The results show that, as it was expected, SSBC is capable to work as a mechanical shear fuse and dissipate energy effectively in both MRFs and EBFs without any material yielding.

RBS:

SLF:

RBS:

Analytical study of moment resisting frames retrofitted with shear slotted bolted connection

Slotted Bolted Connection (SBC) and Rotational Slotted Bolted Connection (RSBC) are two types of friction dampers that have been developed and studied over the years. However, the application of SBC and RSBC are limited mainly to members with axial or flexural dominated behavior. In this study, a new type of friction damper, namely Shear Slotted Bolted Connection (SSBC) is proposed to extend the application of SBC in members with shear dominated behavior. First, the details and applications of SSBC in various lateral load resisting systems are described. Finite-element models are then developed to investigate the behavior of SSBC in Moment Resisting Frames (MRFs). A nine-story prototype MRF is retrofitted by SSBC based on two proposed design philosophies and the performance of the structures is assessed using Nonlinear Static Procedure (NSP). A practical optimization method is then utilized to improve the behavior of the frames. Finally, the effectiveness of SSBC in improving the performance of the optimized structures is verified through Nonlinear Dynamic Procedure (NDP).

Development of Structural Shear Fuse in moment resisting frames

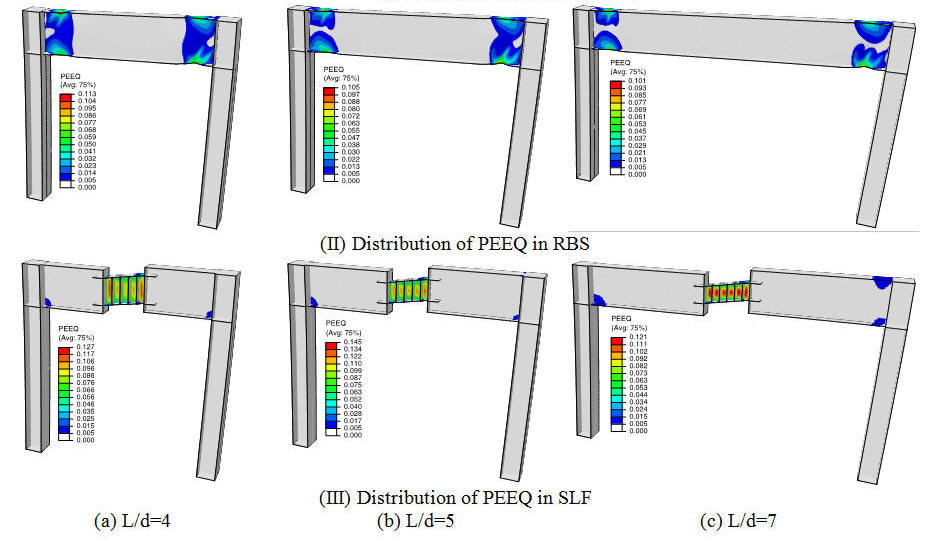

Codes require that the span-to-depth ratio of the beams in moment resisting frames (MRF) should be limited to guarantee the development plastic hinges with a sufficient length at beam ends. This requirement limits the application of MRFs mostly in framed-tube structures; consist of closely spaced columns in perimeter that are tied by deep beams. In addition, in the current design procedure of steel MRFs, the strength and stiffness design of the structure are coupled, which often leads to overdesigned structures and foundations. To overcome the abovementioned limits, in this paper a new replaceable shear structural fuse is introduced for MRFs. The fuse is a shear link that is designed as a sacrificial component by weakening the shear strength of a segment at the middle of the beam to dissipate the seismic energy by shear yielding with stable hysteretic behaviour. Two alternative details are proposed for the replaceable link, applicable in design of new and retrofit of existing structures. The monotonic and cyclic behaviour of a single span-single story MRF with various beam span-to-depth ratios equipped with the proposed shear fuse is investigated through finite element modelling, verified using experimental data. The performance of the proposed system is compared with the conventional MRFs with flexural plastic hinges at reduced beam sections. In general, the shear yielding of the link is shown to be a great replacement for flexural hinges in MRFs, especially with low beam span-to-depth ratios, offering a ductile structural fuse with the ability to be replaced after an earthquake.

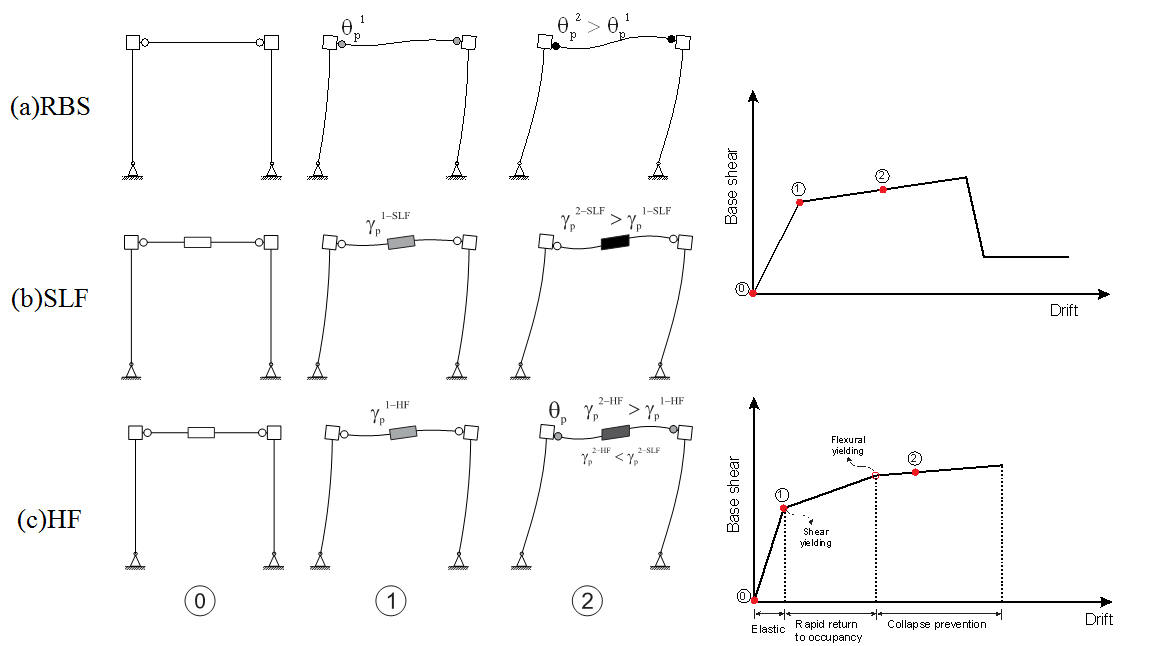

The design of SLF was based on the concept of replacing the flexural plastic hinges of RBS ( REF _Ref394011596 \h \* MERGEFORMAT Figure 15(a)) with nonlinear shear behaviour of the link at the mid-span ( REF _Ref394011596 \h \* MERGEFORMAT Figure 15(b)). This goal was achieved by using generally recommended link over strength factor of 1.5 proposed by the codes. Numerical analysis results also confirmed that no nonlinearity occurred at the beam ends of SLF models designed based on the proposed concept. In this section a new design concept is proposed to make use of RBS and SLF potentials. As shown in REF _Ref394011596 \h \* MERGEFORMAT Figure 15(c), in the proposed system the link yields initially, followed by the onset of flexural yielding at beam ends due to the link overstrength as the lateral displacement increases. The frame designed based on the proposed concept distributes the dissipated energy within the shear link and beam ends; this system is called Hybrid Frame (HF). HF also diminishes the concern of fracture of the beam by distributing and consequently alleviating the strain demands in flexural and shear hinges. As shown in REF _Ref394011596 \h Figure 15(c), the resulting lateral response of HF provides for three performance levels at different levels of seismic hazard as follows: (i) Elastic behaviour: under service loads, the entire structure remains elastic. (ii) Rapid return to occupancy: under moderate lateral loads, the replaceable links yield in shear while the rest of the structure remains elastic. (iii) Collapse prevention: formation of plastic hinge at beam ends.